Quality Process

At BESA, we are committed to continuously enhancing our quality control processes to ensure customer satisfaction. Our goal is to provide not only the most competitive pricing and delivery in the market but also to guarantee 100% quality in all our products. To achieve this, BESA is integrating state-of-the-art technology and advanced testing equipment into our operations. We are also implementing rigorous internal protocols, such as the BESA Sourcing Approval Integration (SAI) and the Vendor Management Program (VMP). These protocols allow us to maintain a secure supply chain with full traceability, ensuring that every product can be traced back to its original source.

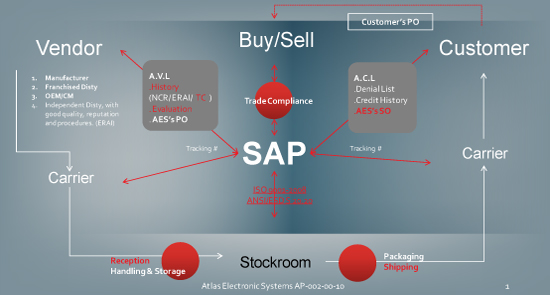

Sourcing

All lead-time and spot buys are procured through Authorized Distributors or direct channels, ensuring that parts are fully traceable. Traceability is clearly indicated on the packaging via lot codes, batch codes, and date codes.

Inspections

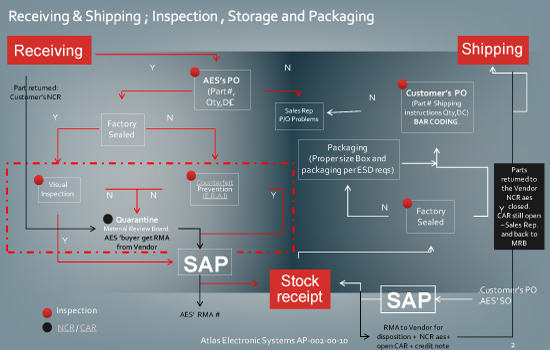

Our Quality Control process is governed by strict guidelines, including

01 Vendor Management Program

Continuous supplier monitoring to ensure compliance.

02 Visual Inspections

Careful examination of all open bag material

03 Traceability

Verification that all materials are in factory-sealed packages, with labels attached to ensure traceability back to the factory.

01 Moisture Barrier Bags (MBB)

Used for all repackaged items.

02 Moisture Sensitivity Level (MSL) Labels

Included with all repacked items.

03 Dry Packs

Equipped with desiccants and Humidity Indicator Cards (HIC) to protect sensitive components, especially modules